These tests are the most accurate for predicting the behaviour of a pile under permanent load, but they are also the most time consuming and expensive.

Force is applied to the pile by either:

(i) an hydraulic jack placed on its top and pushing for reaction against either an anchored beam or a pile of weight (called here HEAD LOAD TEST); or

(ii) a disposable jack placed within the pile shaft which pushes up and down with equal force on the shaft length above it and the shaft plus base below it, (called an INTERNALLY JACKED TEST).

The most commonly used standard specification in South Africa is SANS 0120:Part 2 Section F – 1983 Piling, Clause 7.4 British Procedure. This requires the load to be imposed in increments of 25% of working load (WL) up to WL; then unloaded quickly; then loaded in increments of 25% of WL up to 150% of WL; then unloaded quickly. At each increment of load it is to be held constant until the rate of settlement is <0.2mm per hour, or for 24 hours, whichever comes first. For piles in clay soils this test can take more than a full week to do.

An alternative specification is the “Quick Load Test Method” of ASTM D1143 “Standard Test Method for Pile Under Static Axial Compressive Load”, which can be completed in one day.

Head load test using an anchored beam.

Internal jack being installed in a bored pile.

With both methods of load application Tambew recommends the determination of further information about the mechanics of the pile’s behaviour using Strain Rods. See LOAD TRANSFER TO SOIL on page LOAD TESTING.

Maintained load tests are traditionally used alone on South African sites, but if combined with one of the QUICK LOAD TESTS the accuracy of interpretation of the quick test is greatly improved and many more piles can be tested. This gives improved confidence and probable cost reduction.

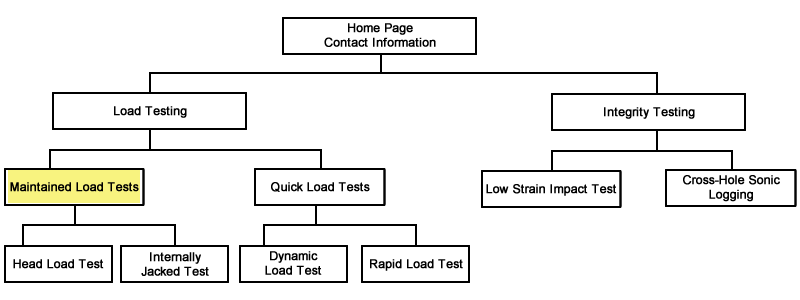

TAMBEW’S WEBSITE ARRANGEMENT