In this test method the head of the pile is exposed to a depth of approximately one diameter and two strain gauges and two accelerometers are attached to it. A large mass is dropped onto a wooden pad on top of the pile, sending a short duration (3 to 8 millisecond) stress wave travelling down it. The stress wave compresses the pile causing relative movement between the pile and the soil which induces shear stress at the boundary between them. This shear stress reduces the magnitude of the stress wave.

At the bottom of the pile the wave causes downward movement of the toe (inducing bearing stress) and is reflected as a tension wave. The tension wave also causes relative movement between the pile and the soil, inducing shear stress in the opposite direction to that induced by the compressive wave, and also reducing the magnitude of the stress wave in the pile.

“Stress wave” theory is used to model this behaviour, implemented in proprietary computer programs.

Measurements from the instruments attached near the top of the pile are converted into force and velocity at the pile head and graphs of these parameters are plotted v. time.

The interpreter of the test adjusts the inputs to the program that theoretically models the behaviour of the pile until the program produces the same graphs as the (dynamic) test measurements. From the theoretical model and using empirical adjustments, the predicted behaviour of the pile under static load is derived.

Tambew does not presently offer this test because: a) the only people able to do the interpretation of the test measurements are in other countries; and (b) the Rapid Load Test offers a better opportunity for widespread use in South Africa. See page RAPID LOAD TEST.

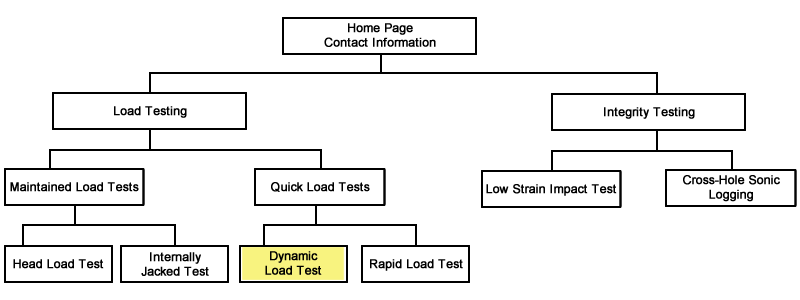

TAMBEW’S WEBSITE ARRANGEMENT